January - December 2017

I have been ducking-out of every self-imposed responsibility to my old

place of work and beavering away at installing an electronic power

steering (EPS) Easysteer column and tested it today (19th Mar 2017).

Indeed, when Rick at Easysteer asked me to speck-out the feasibility of

fitting a drinks can in the place where the EPS motor would have to

go.... it was indeed found that there might be enough space available.

Oh, '....shining and free.... the cold graveness of iron.... the keen,

unpassioned beauty of a great machine....' (Rupert Brooke, 1887-1915, in

The Great Lover).... but t'was non-alcoholic.

Interesting times because the Dr advised not to drive at the moment (as

of late Feb 2017) for mental health reasons, so getting petrol means

using a jerry can and going to the garage by train or taxi (the latter

would seem best if carrying petrol, officer) - even more interesting

because the people I talk to think I am mad to be taking Dr's advice,

but then the Dr thinks I am mad, too, so its a vicious circle. Still,

the bulk of the worst stuff, namely losing consciousness at 'work' and

then being engaged in various aggressive conversations with a distinct

visionary element, seems to be subsiding and perhaps some automotive /

electromechanical progress has been made... mind you, 'working', or

rather volunteering, in a pharmaco-chemistry type of environment where

drinks, etc, of possibly dubious nature sometimes appear, does not

inspire much confidence in humankind (well, I guess someone's got to

test 'em ;-). Finding a representative of your employer miraculously

present at your first local psychiatric appointment does not help to

inspire much confidence either - the truth is indeed stranger than

fiction and comits me to following a path of no-return, well, at least

not right away, anyway. NHS donor card filled in, anyway, to appease the

great health service of our nation.

Here are some views of the underside of the newly fitted motor with the

lower-power connections in place.

Closer to the end of Mar 2017 and its looking promising now. I filed one side of the hole in the plastic mounting bracket for the switches and it is now held on to the column by the screw and some Sugru, for luck. I will try to complete re-assembly in the next day or so with the (in)expertly heatgun-treated ducting now in place. It all looks pretty promising and makes a huge difference to the feel of the car in a few trials, strictly around the garage yard, officer.

I now just need to re-mould the fibre cover that goes under the dash-board so that it fits reasonably well around the base of the electric motor. I still need to refit the steering wheel properly and must check if the horn still works because the Easysteer man said that I might need a wireless one!!

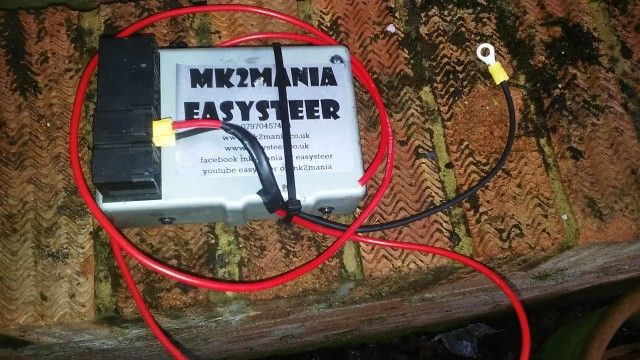

One final technical trick that I forgot to mention is attaching the ECU box to the wiring loom with a couple of Wilko's best self-releasing cable ties ( ;-0 ) and note also the intervening bicycle handle-bar grip as a bit of padding to protect the wires which is held on with some tape for good measure. It seems to be working well, or at least when the rheostat knob is turned towards maximum, the steering is very, very light, even at standstill. Other quick checks in the yard showed that it all works well and the Sugru seems to be holding fast.

Dosing the fibre-panel that goes above the driver's footwell with hot water and re-shaping it over a pudding bowl followed by weighing-it down with a couple of bricks has allowed it to be re-fitted reasonably well. The steering wheel has been aligned and torqued-up and I forgot to mention its all running from a nice little 40 Amp fuse. Still in late March 2017 and all seems to be awesome - even the horn works!

Ok, so we need to drum-up a welder to sort out the rust, and the front wings and bumper are therefore removed to facilitate the welding process, which is put on a backburner for a while anyway since it will require a welder with a trailor.

Mid-April 2017 and now I am converting the other 1.7, namely Deep Blue. A not so elegant removal of the ignition switch backplate (destructively, with a hacksaw) is in progress, or lack thereof, but I have a slightly battered spare left over from Red Bess, which will do with a couple of new bolts. Its all a bit more apart now with the ignition switch and column bracket removed.

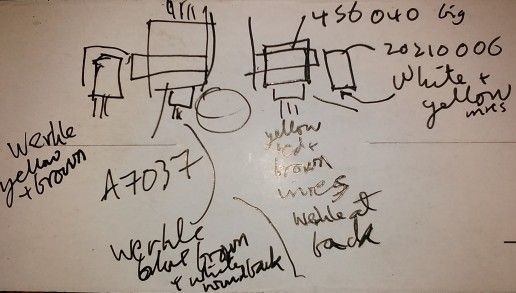

A bit of a wiring diagram to show the positioning of the relays for when they are put back into place, but please note, dear reader, that one of them will never be fitted back in its rightful place due to physical constraints imposed by the bulk of the electric motor on the steering column.

A long gap in comms from April through till mid-June 2017, but here is the latest set of photos showing the new EPS being fitted to the beautiful deep blue 1.7....

A bit of an issue with the low-power wiring arose due to my ineptitude but all was correctified in the end.

I had the black and white wires in the above right-hand photo the wrong way round at this point which caused the power steering not to work. However, swapping them easily rectified the situaish. I also remember that one of those wires had to be connected elsewhere in the end to make sure that the PS only came on when the ignition was switched on, otherwise it stays on all the time and presumably drains the battery or knackers itself in no time at all. So whilst the black and white wires look wonderful slotting into that connection block (above right), it is actually incorrect to wire it this way, sorry!! Just follow the instructions and find a suitable free connector to connect the wires to - there are enough if you do not have too many auxillary instruments, I guess.

Now at the end of June 2017 and a bit more progress has been made with cable ties and foam rubber padding, etc, to hold the ECU in place and to keep Honey smiling. Actually, I had a bit more work than expected whilst fitting the column switch mounting back correctly. I had to use a plastic spacer (chopped-off bit of cable-tie) of the right width to get the spacings right for the horn switch mechanism (brushes and slip rings) to fit together correctly without excessive friction and the end result was found to work fine. I am holding these bits together with black silicone sealant rather than Sugru in case disassembly should be required.

A bit of bathwater being used to re-shape the underdash trim panel and it is subsequently found to fit just about alright.

This time I have used the fuse supplied with the EPS kit and its wired-in as below. The setup still seems to work fine, so attention will now turn towards the rear, nearside spring which seems a bit saggy, as well as the front seat belts which don't retract very well. The latter have been sent away for refurbishing (early July 2017). I must call them to see what options are available for the belts and I must also check the air vents are working fine with all the remoulding done to the ducting by use of a borrowed heat gun. The steering wheel may also need a check on the alignment - cursing myself for forgetting to do this.

So, now heading towards mid-July 2017 and the rear spring on Deep Blue has been removed and replaced with one from the Volvo300mania website. Some issues with removal of one of the bolts which will necessiate its replacement with a new item, to be procured.

Tales of all of this progress are being pondered intensively by Henry the cat.

Deep Blue then receives some fairly consolidated attention to its seat belts, which were removed successfully while a spare 2 or 3 belts were refurbished commercially, around mid-July 2017. Fitting the re-webbed belts to the car has made a fabulous difference to their ability to retract and, as Henry, with a slightly matted coat, will confirm, this has made a big impression of progress in my pea-sized brain. Note that when one's social life consists of imagining what a kind-hearted cat would say to you in a particular set of circumstances, you are probably in the realm of needing further help and indeed the dawn lights will herald a new day in which I will, alarm-clock permitting, make a trip for another appointment with our glorious health service. It must be that 2am confidence, following a sip or two of Green Mark vodka, which is buoying up my spirits. Mind you, this weather, one only has time for a couple of sips before it (like hope) evaporates.

At the end of Jul 2017, Red Ness has been taken by lorry to the welder who has moved to some distance of about 20 miles from where he was based before, all of which adds to the general complexities. I forgot to take any photos of the lorry but had to walk about 4 miles to the nearest village to get the bus and train home. Anyhow, I did a painting on the way back which is reproduced here - its more scrambled egg than Michelotti, but doesn't look too bad given that I haven't put hand to brush for about 30 years ;-0

Now in mid-Aug 2017 and steering too close to the malt whiskey for the benefit of my sanity, although I begin to wonder if it is for the benefit of my insanity. Heaven help anyone who crashes in to me in future and traces my web-presence to this site - the relaxation induced on finding I'm a complete nutter will surely give them a cardiac arrest. Between making efforts to restore my sanity to as hip-a-state as the cat below, I am reduced to feeling as daft as a brush whilst trying to replace the carpets on a Rover P5B.

Anyhow, back to the 340's and, on remembering to actually breath, I can comment on progress being made in that department. The rules of the game were set a couple of years ago when I made a wish-list of things to be done and indeed the last few weeks of not being able to drive (still on Dr's orders) have allowed me to complete a bit of touching-up to the door-bottoms and checking of the cleanliness of the speedo innards.

Deep Blue is now in as completely restored a state as she can surely be. A lift from a former colleague of mine to inspect the works of the welder commissioned to restore Red Ness does allow a visit to the ecstatically beautiful countryside.

A bit of work on the 360 allows me to tackle some of the items on the wishlist for that one, as of late Aug 2017. The main issue, indeed not one on the wishlist, is that it will not start unless petrol is poured into the carburettor and then it only keeps running for a split second or so. So with much despair in my soul, I replaced the fuel filter and pump, to no avail. Another change of the pump proved again to be of no avail, too. Thus a leccy fuel pump which I had bought for another car a year or two ago was resurrected from storage and pressed into action.

A bit of temporary wiring proved that the new pump ticks over rather quickly, but it certainly is effective at circulating the fuel and allowing the car to start. Hence efforts are made to make this a more permanent fixture, including the finding of a suitable free connector next to the fuse box to attach it to (think its to do with optional foglights or sumthin). Here's how we are looking after a day or so with improved connectivity for the earth wire by application of some conducting paint, some plumbers PTFE tape to stop leaks and the construction of a blanking plate to cover the hole for the old mechanical fuel pump. Mounting the pump to the power steering pipes, cushioned by old rubber piping, seems to allow it to jiggle about not too noisily. Whilst coming to terms with the loss of the mechanical fuel pump and conversion of the system to electronic gadgetry, I get a chance to repair the wire to the rear windscreen heater.

Now in early Sept 2017 and things are progressing with Red Ness at the welders, as the following should demonstrate.

All looks pretty good with the front wheel arch work but there's a bit of a stalemate with the rear valance until a phone call from the welder prompts me to dig around in the roof and exactly the right panel is found and delivered by hand the very next day. There might be an issue with the rear wheel arch too, as shown below, and the welder, rather optimistically, wants to replace the front wings due to rust around the wheel arches, but I am not sure that those available will be any better, but who knows.

I also have a note that there's rust in the doors which the welder should look at, so a reminder to him is sent. We bumble on.

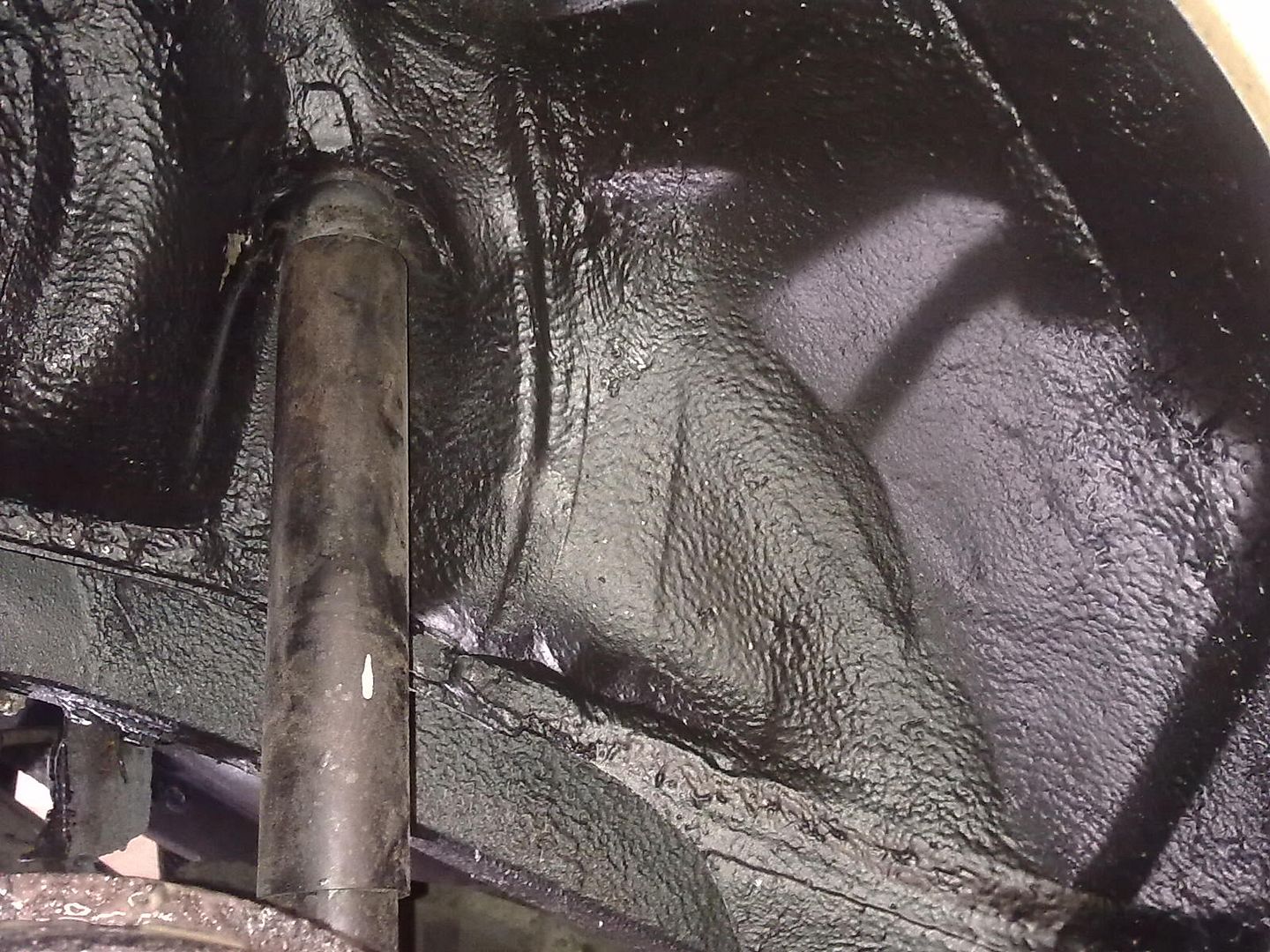

Now in mid-Sept 2017 and I am semi-sort-of given the all clear to start driving again, so manage to get to see the welder again and he confirms that panels and parts are turning-up at a steady rate, so he is about to make further progress. Here are some views of the rust found around the rear sub-frame.

Now into mid-Oct 2017 and a trip or two over the last couple of weeks to the welder has yielded some interesting pictures of progress which are reproduced below.

It turns out that he has had to do a lot more than I expected including replacing the fuel tank due to rust on the top of the old one and big chunks of the wheel arches, cross-member, boot floor, etc, but the march of progress must be un-erring.

The gearbox mounting bushes that I bought a decade ago or so are going to come into their element since at least one of them on the car has been damaged by past welding efforts. As for the under-floor welding, that was then, but this is now....

Now in late Oct 2017 and another trip to the welder to try to sort out an issue with the new petrol tank (which is for the old model 340) reveals that he has been beavering away at fitting it all back together and waxoyling where its needed. The front is still to be tackled. He is going to try to modify the tank opening so the original sender unit will fit.

Now in early-Nov 2017 and have been fiddling about with the 360, mainly to improve the feel of the brake pedal. A fairly quick bleed-through of the system showed that there was some air in the pipes to the rear brakes. Job done sorted.

See it, say it, sorted. Well, that isn't true for my efforts to wire-in a bleeper for the indicator light flasher unit so that I can be reminded that the indicator or hazard lights are left on. I wired it in and it works semi-OK when the engine is off, but as soon as its running, the bleeper makes odd noises all the time. So, I will try one more bleeper and see if it is less prone to interference or poor earthing, etc, and if not then the idea will have to be confined to a back-burner for a bit while I work out what to do, but its not terribly important anyway.

Late Nov 2017 and more issues arise whilst trying to get the 360 back into use as daily transport - the ignition starts cutting-out again. This immediately brings back memories of struggling with the connections on the back of the fuse box and so a few days are spent removing it, cleaning it and the connection blocks, testing a 'new' fuse box in my collection (which still doesn't seem to work) and generally slowly getting it all back together again with the original fuse box. I don't like this job, mainly because its high stress to be lying on your back in the driver's footwell, cursing and trying to get the fuse box screws back into place. Anyhow, the end product seems to be a working car!

Early Dec 2017 sees the Red Ness monster finally returned from the welder with much undercoat visible (and some invisible) in various places. The plan is to start rubbing this down for a respray with aerosols (hopefully it will work) in the second half of December and onwards into the new year, weather-permitting somewhat!

Coming to the close of 2017 Blue Bess narrowly misses rear-ending someone - my fault - it was close. I will keep trying to do better. However, the next day she developed power problems and had to be low-loaded back home from the A3.

Here's hoping that we get some good luck soon.

So, what's to come in 2018?

top